Semua produk

-

AlexanderPemasok yang dapat dipercaya

AlexanderPemasok yang dapat dipercaya -

LouisSenang bekerja denganmu.

LouisSenang bekerja denganmu.

Low High Pressure Boiler Economizer dengan Max 60t/h Produksi uap dan sirkulasi alami

Hubungi saya untuk sampel gratis dan kupon.

ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan 24 jam bantuan online.

xDetail produk

| Jenis | Sirkulasi Alam | Struktur | Tabung api dan tabung air |

|---|---|---|---|

| Tekanan | Tekanan Rendah / Tinggi | Produksi Uap | Max. 60t/jam |

| Gaya | Vertikal | Bahan bakar | Batubara |

| Keluaran | Air Panas / Uap | Perawatan permukaan | Dilukis |

| Od pipa telanjang | 25-1650 mm | Ketebalan pipa telanjang | 2-40 mm |

| Ketebalan sirip | 0,6-3,0mm | Tinggi sirip | 5-30 mm |

| Pitch tabung sirip | 5-30 mm | Panjang tabung sirip | ≤12000 mm |

| Bahan | Baja karbon, paduan, baja austenitik | ||

| Menyoroti | Max 60t/h Boiler Produksi Uap Economizer,Low High Pressure Boiler Economizer,Penghematan kotel sirkulasi alami |

||

Deskripsi Produk

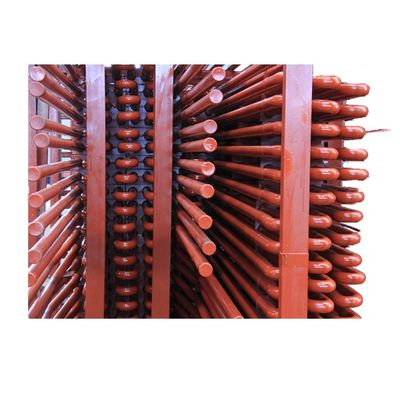

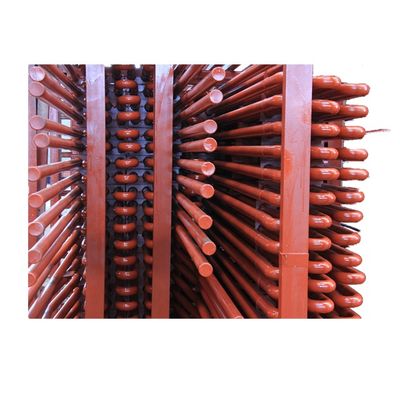

Perangkat Penukar Panas Economizer Boiler Gas Buang Tekanan Rendah / Tinggi Dengan Tabung Sirip

Economizer Boiler

Pendahuluan

Economizer memainkan fungsi kunci dalam memberikan efisiensi termal boiler secara keseluruhan yang tinggi dengan memulihkan energi tingkat rendah dari gas buang sebelum dibuang ke atmosfer. Mereka memulihkan energi ini dengan memanaskan air umpan boiler. Economizer adalah permukaan perpindahan panas tubular yang digunakan untuk memanaskan air umpan boiler sebelum masuk ke drum uap atau permukaan tungku, mengurangi biaya pengoperasian dengan memulihkan energi ekstra dari gas buang.

Prosedur

Economizer mengurangi potensi kejutan termal dan fluktuasi suhu air yang kuat saat air umpan memasuki drum atau dinding air. Mereka juga membantu memenuhi peraturan lingkungan yang ketat yang membatasi emisi nitrogen oksida dan sulfur dioksida. Koefisien perpindahan panas sisi gas jauh lebih rendah daripada koefisien sisi air, sehingga permukaan tabung luar dapat diberi sirip untuk meningkatkan area perpindahan panas. Desain economizer bertujuan untuk mencapai perpindahan panas yang diperlukan dengan biaya minimum, dengan kecepatan gas buang maksimum yang diizinkan menjadi kriteria utama.

Spesifikasi

| Nama (satuan) | Spesifikasi (mm) |

|---|---|

| Pipa telanjang (OD) | 25-1650 |

| Pipa telanjang (Ketebalan) | 2-40 |

| Sirip (Ketebalan) | 0.6-3.0 |

| Sirip (Tinggi) | 5-30 |

| Pitch ulir tabung sirip | 5-30 |

| Panjang tabung sirip | ≤12000 |

Material:Baja Karbon, Paduan, Baja Austenitik (Nikel dan Kromium atau Mangan)

Kontrol Kualitas

- Laporan uji dampak dan perhitungan kekuatan dengan informasi material yang diterapkan

- Laporan 100% NDT (pemeriksaan non-destruktif) dari pelat baja, tabung, dan elektroda

- Laporan inspeksi uji sinar-X, γ-ray, dan penetran cair (sambungan las) untuk memastikan kualitas boiler

- Laporan uji hidrolik untuk memastikan tekanan kerja standar dan keselamatan

Produk Serupa

Informasi Perusahaan

Sertifikat

Pengepakan & Pengiriman

FAQ

Hubungi Kami

Rekomendasi Produk