-

AlexanderPemasok yang dapat dipercaya

AlexanderPemasok yang dapat dipercaya -

LouisSenang bekerja denganmu.

LouisSenang bekerja denganmu.

Penukar Panas Economizer Boiler Gas Buang dengan Pipa Bersirip untuk Produksi Uap Maks. 120t/j dan Garansi 1 Tahun dalam Sirkulasi Alami

Hubungi saya untuk sampel gratis dan kupon.

ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan 24 jam bantuan online.

x| Jenis | Sirkulasi Alam | Struktur | Tabung api dan tabung air |

|---|---|---|---|

| Tekanan | Tekanan Rendah / Tinggi | Produksi Uap | Max. 120T/H. |

| Gaya | Vertikal | Bahan bakar | Batubara / Gas / Batubara / Panas air |

| Keluaran | Air Panas / Uap | Bahan | Baja Karbon, Baja Tahan Karat, Baja Paduan |

| Standar Bahan | ASTM, EN atau ISO dll. | kisaran berat | Min: 10 ton maks.:1000 ton |

| Proses peleburan | EF+LF + VD | Proses | Bahan-> ingot -> panas/dingin -rolling-> perlakuan panas (normalisasi+ tempering) -> ins |

| Ut Standar | ASTM A388 atau EN10228, dll | Jenis penukar panas | Economizer tabung bersambung H. |

| Jenis tabung | Tabung Double H Felled | ||

| Menyoroti | Economizer Boiler Produksi Uap Maks. 120t/j,Penukar Panas Garansi 1 Tahun,Economizer Gas Buang Sirkulasi Alami |

||

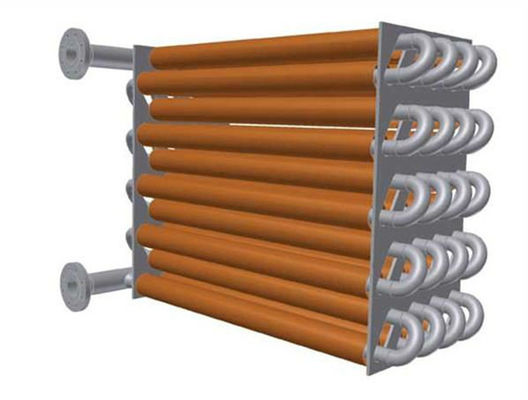

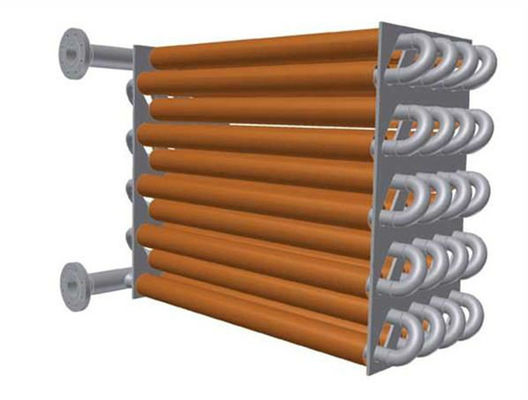

Economizer boiler adalah perangkat penukar panas efisiensi tinggi dengan tabung bersirip yang dirancang untuk memanaskan cairan (biasanya air) tanpa melebihi titik didih cairan. Kami memproduksi tiga jenis economizer boiler:

- Economizer tabung polos

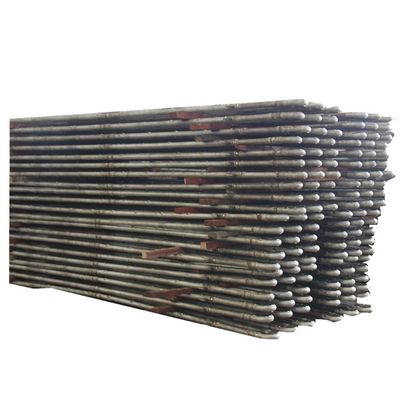

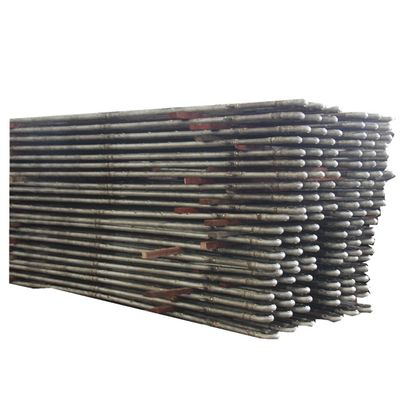

- Economizer tabung bersirip-H

- Economizer tabung bersirip spiral

Economizer tabung bersirip-H adalah desain yang sangat efisien yang terdiri dari tabung bersirip-H. Dibandingkan dengan economizer tabung polos, model tabung bersirip-H menawarkan beberapa keuntungan:

- Peningkatan area penukar panas

- Pengurangan jumlah tabung yang dibutuhkan

- Perluasan area aliran gas buang untuk mengurangi kecepatan aliran dan abrasi

- Tersedia dalam konfigurasi tabung bersirip-H ganda untuk meningkatkan kekakuan pada baris tabung yang panjang

Economizer bersirip spiral mewakili inovasi desain terbaru kami, menampilkan tabung sirip spiral yang secara efektif mengatasi masalah abrasi dan memperpanjang masa pakai.

| Deskripsi | Economizer boiler |

|---|---|

| Material | Baja paduan, Baja karbon, SA210C, SA213T22, dll. |

| Standar material | ASTM, EN atau ISO dll. |

| Dimensi | Kustomisasi |

| Berat | Min: 10 ton Maks.:1000 ton |

| Proses Peleburan | EF+LF + VD |

| Proses | Material→Ingot → Penggulungan Panas/Dingin→ Perlakuan panas (Normalisasi+ tempering) → Inspeksi →pemesinan kasar→UT →Perlakuan panas ke-2 →pemesinan finishing →Inspeksi |

| Standar UT | ASTM A388 atau EN10228, dll |

- Laporan uji dampak dan perhitungan kekuatan dengan informasi material yang diterapkan

- Laporan NDT (pemeriksaan non-destruktif) 100% dari pelat baja, tabung, dan elektroda

- Laporan inspeksi uji sinar-X, γ-ray, dan penetran cair (sambungan las) untuk memastikan kualitas boiler yang lengkap

- Laporan uji hidrolik untuk memverifikasi tekanan kerja standar dan keselamatan